6mm micro reduction motor suitable for precision testing equipment of medical devices and miniature cameras

Type: DC Gear Motor

Performance parameter: 3V 11RPM to 3840RPM

Overview

Product Introduction

Mini hollow cup motor is a type of small electric motor that features a hollow cup design. It is known for its compact size, high efficiency, and low noise operation. This type of motor is commonly used in various applications such as robotics, drones, camera gimbals, and medical devices.

The mini hollow cup motor is ideal for situations where space is limited and weight is a concern. Its small size allows for easy integration into small devices, while its high efficiency ensures optimal performance. Additionally, the low noise operation makes it suitable for applications where noise levels need to be kept to a minimum.

Specification

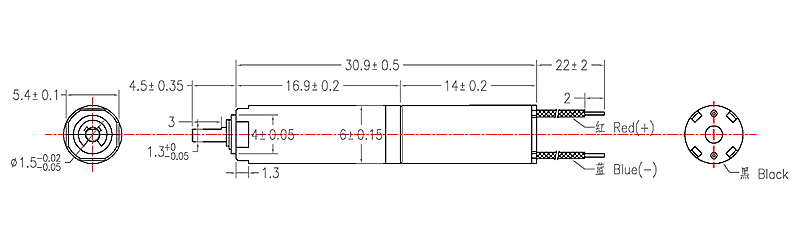

The 6mm micro reduction motor is a highly specialized component designed for precision testing equipment of medical devices and miniature cameras.

This motor is characterized by its extremely small size of just 6mm, making it ideal for applications where space is limited. Its micro design enables seamless integration into precision testing equipment for medical devices, ensuring accurate and reliable operation. In the field of medical device testing, it can contribute to the precise evaluation and calibration of various instruments, enhancing the quality and performance of medical products.

With its high level of precision and reliability, this micro reduction motor is a valuable asset for both the medical device and miniature camera industries, enabling advanced functionality and superior performance in their respective products.

| Model | Voltage | No Load | At Rated Load | Overal Length | Max Rated Torque of Gear Box | Max Instant Torque of Gear Box | Gear Ratio | Gear Box Length | ||||

| Speed | Current | Speed | Current | Torque | ||||||||

| VDC | rpm | mA(max) | rpm | mA(max) | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| FM006006-5 | 3 | 3824 | 30 | 3229 | 100 | 3.3 | 0.32 | 23.7 | 330 | 800 | 4.8 | 9.7 |

| FM006006-6 | 3 | 2855 | 30 | 2411 | 100 | 4.4 | 0.43 | 23.7 | 330 | 800 | 6.43 | 9.7 |

| FM006006-23 | 3 | 797 | 34 | 673 | 100 | 13.3 | 1.31 | 26.1 | 330 | 800 | 23.04 | 12.1 |

| FM006006-31 | 3 | 595 | 34 | 502 | 100 | 17.8 | 1.75 | 26.1 | 330 | 800 | 30.86 | 12.1 |

| FM006006-41 | 3 | 444 | 34 | 375 | 100 | 23.9 | 2.34 | 26.1 | 330 | 800 | 41.33 | 12.1 |

| FM006006-110 | 3 | 166 | 37 | 140 | 100 | 54.3 | 5.33 | 28.5 | 330 | 800 | 110.6 | 14.5 |

| FM006006-148 | 3 | 124 | 37 | 105 | 100 | 72.8 | 7.14 | 28.5 | 330 | 800 | 148.1 | 14.5 |

| FM006006-198 | 3 | 93 | 37 | 78 | 100 | 97.5 | 9.56 | 28.5 | 330 | 800 | 198.4 | 14.5 |

| FM006006-266 | 3 | 69 | 37 | 58 | 100 | 130.5 | 12.8 | 28.5 | 330 | 800 | 265.7 | 14.5 |

| FM006006-531 | 3 | 35 | 40 | 29 | 100 | 221.7 | 21.74 | 30.9 | 330 | 800 | 530.8 | 16.9 |

| FM006006-711 | 3 | 26 | 40 | 21 | 100 | 296.9 | 29.12 | 30.9 | 330 | 800 | 711 | 16.9 |

| FM006006-952 | 3 | 19 | 40 | 16 | 95 | 330 | 32.36 | 30.9 | 330 | 800 | 952.2 | 16.9 |

| FM006006-1275 | 3 | 14 | 40 | 12 | 85 | 330 | 32.36 | 30.9 | 330 | 800 | 1275.2 | 16.9 |

| FM006006-1708 | 3 | 11 | 40 | 10 | 75 | 330 | 32.36 | 30.9 | 330 | 800 | 1707.9 | 16.9 |

|

|

Application

1.Electric toys: mini dc motor can be used to drive small electric toys, such as remote control cars, remote control planes and so on.

2. Household appliances: mini dc motor can be used in household appliances, such as electric toothbrush, electric shaver, etc.

3. Mechanical equipment: mini dc motor can be used to drive some small mechanical equipment, such as small power tools, small robots and so on.

4. Car models: mini dc motor can be used to drive small parts in car models, such as wheels, lights and so on.

5. Medical equipment: mini dc motor can be used for some small medical equipment, such as electric massager, electric suction, etc..

6. Smart home: mini dc motor can be used in smart home products, such as smart curtains, smart door locks and so on.

7. Electronic equipment: mini dc motor can be used to drive some small electronic equipment, such as small fan, small like head and so on.

8. Industrial equipment: mini dc motor can be used in some small industrial equipment, such as small conveyor belt, small mixer.

Details

Customization

We understand the technical and manufacturing challenges motors present and enjoy providing solutions. Through our design we reduce costs and engineering risk, leading to innovative solutions delivered on time and to spec.

Quality Control

Before leaving the factory, the motor needs to go through a series of tests, including: appearance test, size test, performance test, mechanical test, salt spray test, temperature storage test, drop test, noise test.

Qualification

Yichang Boyuan Electronics Co., Ltd. has been specialising in the production and research and development of DC micromotors since 2004. The company owns more than ten invention patents, a core team of 20 people, more than 200 employees, a standardised dust-proof workshop of 4,000 square feet, an independent motor laboratory and automated production equipment, the degree of automation in the production of micro-motor components reaches more than 56%, and the annual output of all kinds of motors is 30 million units.

Every year, the company develops more than 500 kinds of new motor samples, among which the waterproof electric toothbrush motor, radial motion acoustic motor and massage shoe motor have entered the mass production stage. At the same time, the company's automotive door locks, wiper pumps, seat automatic adjustment iron core motors through the manufacturer's audit to become a first-class automotive suppliers.

The company follows the principle of scientific and technological innovation, fine management, strict control of product quality. In 2022, the company successfully passed the IATF16949 automotive quality system certification.

Our Partnership

At present, the company has become ‘Xiaomi’, ‘Philip’, ‘Geely Automobile’ and other well-known enterprises of the first-class suppliers.